Modern manufacturing relies heavily on precision and efficiency to meet the ever-increasing demands of industries. Among the tools driving this revolution, premium CNC machines for manufacturing stand out as the cornerstone of innovation and excellence. These machines offer unmatched accuracy, automation, and versatility, enabling manufacturers to deliver high-quality products across various sectors. Whether you are in aerospace, automotive, or consumer goods, CNC technology transforms how businesses achieve production goals.

What Are CNC Machines?

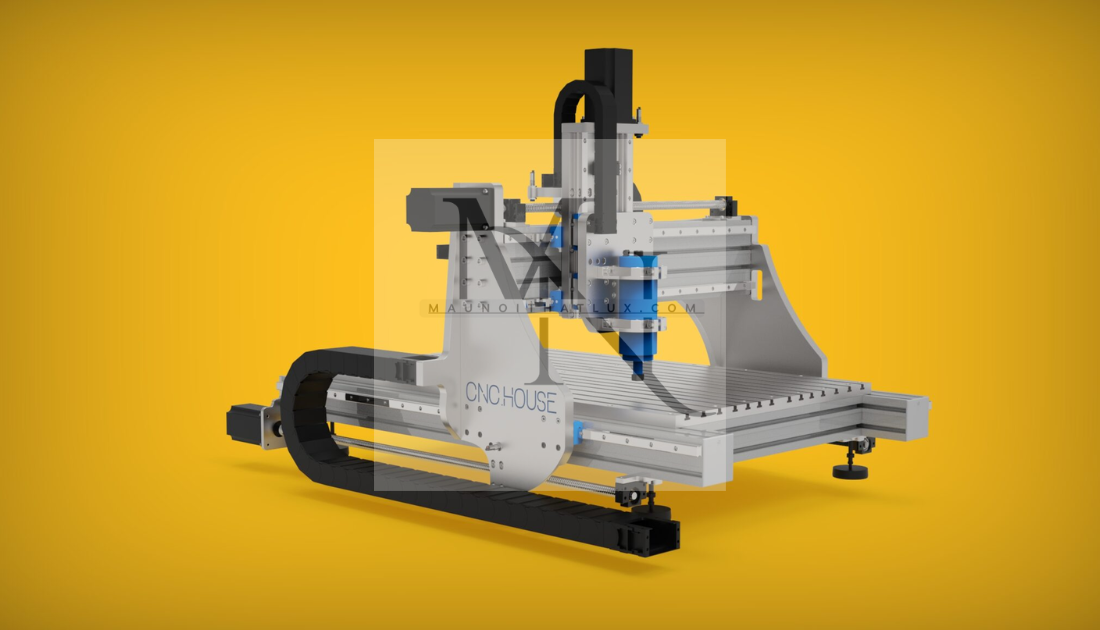

CNC, or Computer Numerical Control, machines are automated tools that use computer programs to control their operations. These machines can perform tasks such as cutting, drilling, milling, and shaping materials with exceptional precision. By replacing manual labor with programmed instructions, CNC machines increase productivity and reduce human error.

Premium CNC machines take this technology a step further by offering advanced features, greater efficiency, and enhanced durability. They are specifically designed to handle complex manufacturing tasks with speed and accuracy, making them a critical asset for modern production environments.

The Importance of Premium CNC Machines for Manufacturing

CNC machines play a pivotal role in optimizing manufacturing processes. Their ability to automate intricate tasks while maintaining high levels of precision has transformed traditional production methods. Here are some reasons why premium CNC machines are indispensable in manufacturing:

1. Enhanced Precision and Accuracy

Premium CNC machines are engineered for unparalleled accuracy, ensuring that every product meets exact specifications. This precision is crucial for industries like aerospace and medical devices, where even minor deviations can have significant consequences.

2. Increased Productivity

Automation allows CNC machines to operate continuously without the need for breaks. This results in faster production cycles and higher output, enabling manufacturers to meet tight deadlines and large orders efficiently.

3. Reduced Waste

By minimizing errors, CNC machines significantly reduce material waste. This not only lowers costs but also supports sustainable manufacturing practices by optimizing resource usage.

4. Versatility

Premium CNC machines can work with a wide range of materials, including metals, plastics, and composites. Their versatility makes them suitable for various industries, from automotive to jewelry production.

5. Cost Efficiency

Although premium CNC machines require a higher upfront investment, their efficiency and durability make them a cost-effective choice in the long run. Reduced labor costs and minimal downtime further enhance their value.

Key Features of Premium CNC Machines

Premium CNC machines are equipped with advanced features that set them apart from standard models. These enhancements enable manufacturers to achieve greater precision, flexibility, and ease of use.

1. Multi-Axis Capabilities

Modern CNC machines often feature multi-axis configurations, such as 5-axis or 7-axis systems. These machines can perform intricate operations by moving the cutting tool or workpiece along multiple axes, resulting in complex geometries and superior finishes.

2. High-Speed Machining

Premium CNC machines are designed for high-speed operations, which reduce production time while maintaining accuracy. This feature is particularly beneficial for industries that require rapid prototyping or mass production.

3. Automated Tool Changing

To streamline operations, many premium CNC machines include automated tool-changing systems. These systems allow the machine to switch between different tools seamlessly, increasing efficiency and reducing downtime.

4. Integrated Software Solutions

CNC machines are powered by sophisticated software that enables precise control and customization. Premium models often include advanced simulation tools, real-time monitoring, and user-friendly interfaces for seamless operation.

5. Durability and Build Quality

Premium CNC machines are constructed with high-quality materials and components to withstand demanding industrial environments. Their robust build ensures long-term reliability and consistent performance.

Applications of Premium CNC Machines in Manufacturing

The versatility of CNC technology makes it a valuable asset in various industries. Premium CNC machines are particularly beneficial in sectors that demand high precision and complex designs.

Aerospace Industry

In aerospace manufacturing, precision is paramount. Premium CNC machines are used to create intricate components such as turbine blades, engine parts, and airframe structures. Their ability to work with advanced materials like titanium and composites ensures superior quality.

Automotive Industry

CNC machines are indispensable in automotive production, where they are used to manufacture engine components, transmission parts, and custom designs. The speed and accuracy of premium CNC machines allow manufacturers to meet the high demands of this industry.

Medical Industry

The medical sector relies on CNC technology for the production of surgical instruments, implants, and prosthetics. Premium CNC machines ensure that these products meet stringent quality standards and provide a high level of customization.

Electronics Industry

From circuit boards to enclosures, CNC machines play a vital role in electronics manufacturing. Premium models enable the precise machining of small, intricate parts that are critical for electronic devices.

Custom Manufacturing

For businesses that specialize in custom products, premium CNC machines offer the flexibility to handle unique designs and one-off projects. This capability is particularly valuable in industries like jewelry, furniture, and artistic creations.

How to Choose the Right Premium CNC Machine

Selecting the ideal CNC machine for your manufacturing needs requires careful consideration of several factors. Here are some tips to guide your decision:

1. Define Your Requirements

Identify the specific tasks and materials you will be working with. Whether you need a machine for large-scale production or intricate custom work, understanding your needs is the first step.

2. Evaluate Specifications

Examine the machine’s capabilities, such as speed, precision, and axis configurations. Ensure that these features align with your production goals and complexity requirements.

3. Consider Software Integration

Look for machines that offer intuitive software solutions and compatibility with existing systems. Advanced software can enhance productivity and simplify operations.

4. Assess Build Quality

Invest in a machine with a robust construction and high-quality components. Premium CNC machines are designed for durability, ensuring consistent performance over time.

5. Budget and ROI

While premium CNC machines come with a higher price tag, their efficiency and long-term benefits often justify the cost. Consider the potential return on investment before making a decision.

Benefits of Premium CNC Machines for Modern Manufacturers

Upgrading to premium CNC machines offers numerous advantages that can transform your manufacturing operations. Here are some key benefits:

Improved Product Quality

Premium CNC machines ensure that every product meets the highest standards of quality, reducing defects and enhancing customer satisfaction.

Faster Time-to-Market

High-speed machining and automation enable faster production cycles, allowing manufacturers to bring products to market more quickly.

Scalability

With their ability to handle both small-scale and large-scale production, premium CNC machines provide the flexibility needed to adapt to changing demands.

Reduced Downtime

The reliability and durability of premium CNC machines minimize downtime, ensuring uninterrupted operations and higher productivity.

Conclusion

Premium CNC machines for manufacturing are at the forefront of modern industrial technology. Their precision, efficiency, and versatility make them indispensable tools for industries that demand excellence. By investing in these machines, manufacturers can achieve higher productivity, lower costs, and superior product quality.

If you’re looking to enhance your manufacturing capabilities, explore the wide range of premium CNC machines available today. With the right equipment, you can unlock new levels of innovation and stay ahead in the competitive manufacturing landscape.